New!! Planning a Lean Healthcare Accelerator Experience in Japan, October 2025!

What if your team could see, firsthand, how some of the world’s most respected hospitals integrate Lean thinking into daily practice—not as a project, but as a culture?

I’m thrilled to announce a new opportunity: I’m organizing and leading Lean Healthcare Accelerator Experiences in Japan, with the next one taking place October 26–November 1.

This is more than a tour—it’s an immersive experience designed for healthcare leaders who want to strengthen patient care, staff engagement, and operational performance through sustainable improvement practices.

I’m partnering with two outstanding colleagues: Dave Fitzpatrick, a Canadian who has lived and worked in Japan for many years and has extensive experience facilitating study missions; and Reiko Kano, a bilingual Lean and TPS expert with deep healthcare experience in both the U.S. and Japan. Dave and Reiko are the co-founders of Zenkai Improvement Partners, and I’m proud to collaborate with them on this initiative.

If you’re interested in joining us—or if you’d like more details—please reach out. The program cost is $9,500 USD, excluding international airfare. Early bird and group discounts are available.

Some of highlights of these experiences:

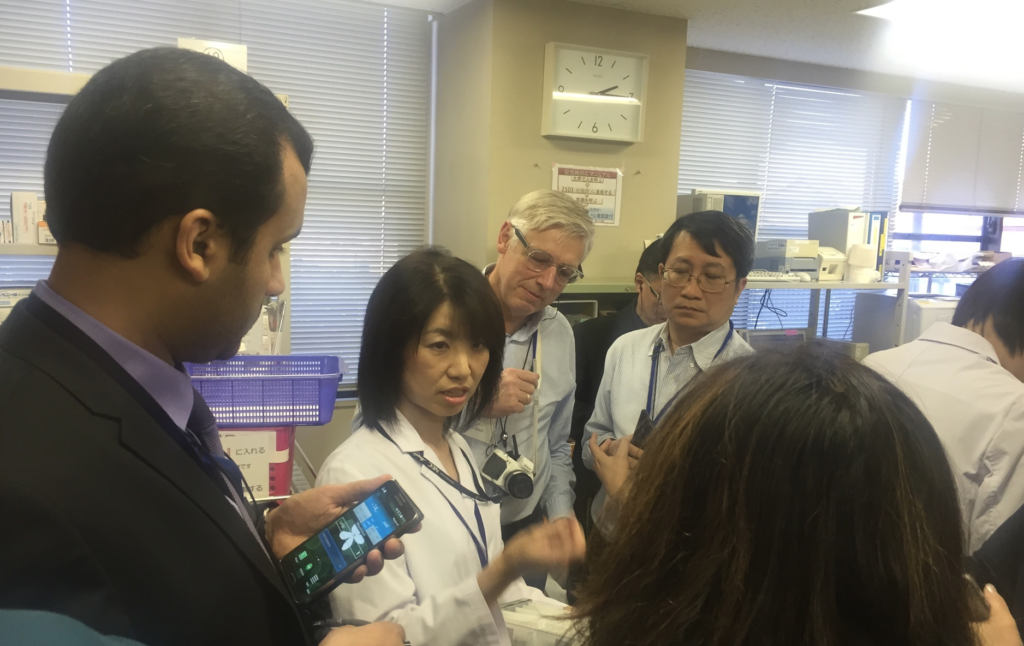

Curated visits to three of the top Lean healthcare facilities in the nation with time allocated for discussions with the lean leaders in each of the organizations.

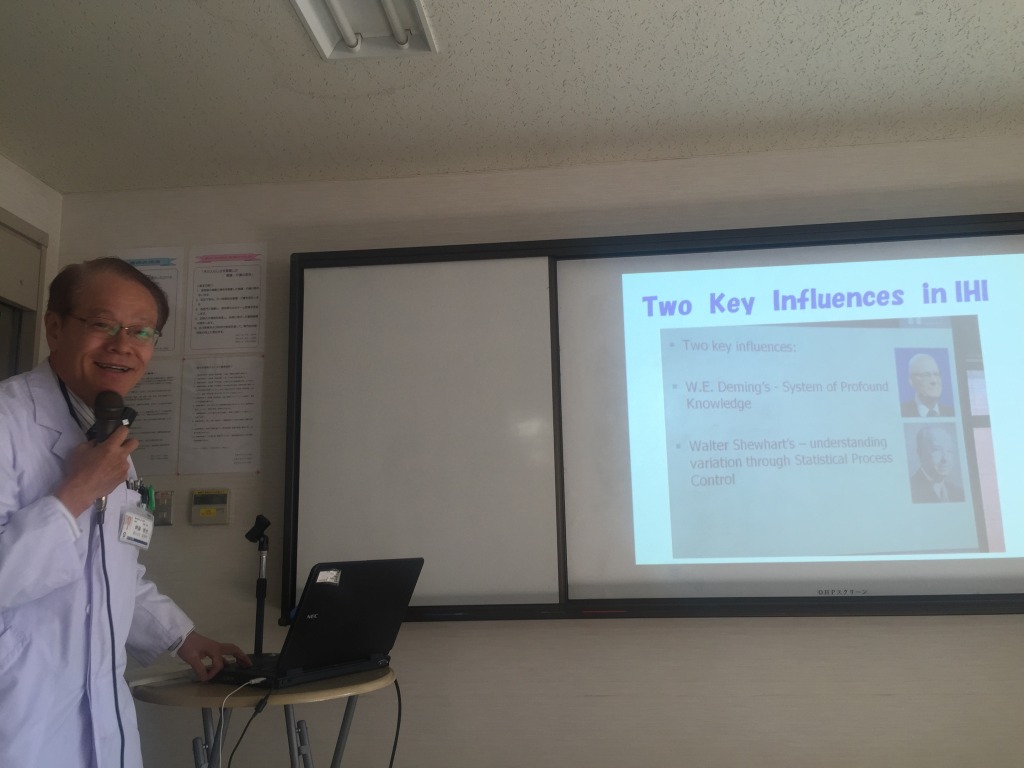

An in-depth study experience with the founders of Japan’s “Doctors for Tomorrow” initiative who are using the principle of TPS to make medical mistakes a thing of the past.

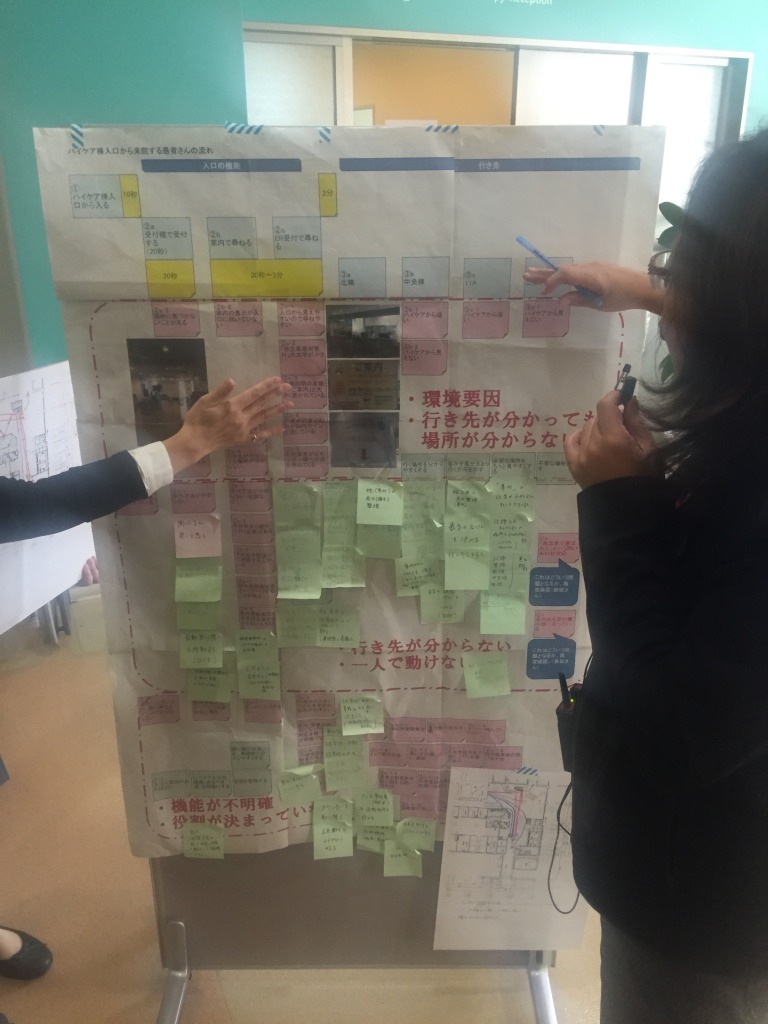

Lean leadership seminars and a hands on process improvement activity that will expose participants to a TPS style approach to improvement.

A Total Quality Management seminar with a lifelong quality manager from Toyota Motor Corporation. Learn why TQM is a vital part of any discussion of TPS and how the SDCA cycle is critical to quality assurance alongside the PDCA cycle.

A visit to a medical device manufacturer (location yet to be decided)

A factory visit to a prestigious supplier into several industries including automotive. The owner and president will share their insights into what lean leadership means for them and how they have developed the culture of always setting stretch targets to move their company forward.

Oh, and we’ll have some fun exploring Japanese culture, food, and more.

… it’s the experience of a lifetime and a great way to get inspired and bring ideas home to your team and organization… not just a bunch of tools, but deep (even profound) lessons and principles…

Quick Details About The Trip for Busy Healthcare Leaders

What’s included in your registration fee?

- Expert logistics and visit planning by an experienced Lean trip organizer

- Translation services from a trusted partner with a great deal of experience with Lean in both Japan and the United States.

- Interaction and discussion with Mark Graban and other experienced Lean leaders

- Site visits

- Training and workshops

- All transportation, hotels, and meals within Japan

The trip runs Monday through Friday in various cities in Japan — starting and ending in Tokyo.

Read Mark Graban’s blog posts about previous trips.

Highlights of Past Tours

In the previous Kaizen Institute tours, our collaboration secured three KAIZEN™ minded hospitals to visit, as well as Toyota and much more!

The site visits have been powerful, but I’ve always been very impressed with the attendees. In the past, they have been very international groups, so you get the opportunity to reflect on what you’re seeing and compare notes about various “Lean journeys” around the world and people’s efforts to create and sustain a culture of continuous improvement.

It’s an incredibly energizing and interesting learning opportunity and experience. Japan is a fun and fascinating place. The tour allows you get a sense of Japanese culture and how that both contributes to a Kaizen culture and creates some challenges that Toyota and other companies have had to work through (see my blog post on this).

My Previous Trip with Honsha:

I had a great experience partnering with my friends from Honsha for a different Japan trip in October 2018. It wasn’t healthcare-specific, unlike the Kaizen Institute tours I have helped with in the past.

Read more about this trip via my blog, and contact me if you’d like more information.

Endorsements from Japan Lean Healthcare Tour Attendees

“If you want to go see and feel Lean and its roots, travel with the Kaizen Institute to Japan.” – Peter Kabel, Microbiologist, Holland

“The opportunity to see and deeply reflect on successful Lean Strategy, Culture and Leadership with lean practitioners from around the world was truly beneficial.” – Pat Kramer, Senior Manager, Lean Consulting, Healthcare Performance Partners

“I sure did learn a lot. Specially about different kind of leadership, where empowering the employee is not just another bit of non-implementable jargon. What blew my mind were the host sites and the depth of Kaizen activities done by the small QC circles. My personal favourite moments were our casual discussions on the bus.” – Mayang Anggarani, Indonesia

Photos

Click here to see Mark Graban’s photos of nothing but food in Japan

Listen to Mark Graban Talk About the Past Trips

Visit the Gemba Academy Podcast episode page

Listen to Mark Graban & Christian Wolcott Talk About the 2014 Kaizen Institute Trip

Visit the Lean Blog podcast episode page

Mark Graban’s Letter to You

Dear Busy Healthcare Leader or Improvement Professional:

I used to be skeptical about taking a long, cramped, tiring flight to Japan just for the purpose of learning about Lean and the Toyota Production System.

There are healthcare organizations that send many people on study missions to Japan each year — Virginia Mason Medical Center and Seattle Children’s Hospital are two of them. These are both great Lean organizations, so they must be onto something. I’ve heard a few people say that you MUST go to Japan if you’re going to understand Lean. Hmmm.

But, wait a minute. Back in 2012, I thought…. I’ve been studying and practicing Lean for twenty years and I’ve never been to Japan. I’ve had mentors who came from Japan, mentors who visited Japan, and mentors who worked in Japan. I mean, I don’t know everything and I’m not perfect, but I think I’m doing OK. There’s always room to get better, but we have books and video courses and all sorts of ways to learn about Lean (did I mention mentors?) without going to Japan.

On the fourth hand, people also come to visit Virginia Mason and to learn from them.

So, maybe you can be successful with Lean either way – go to Japan or don’t go to Japan.

I had always thought that going to Japan might be useful, but it wasn’t necessary. It’s not a “must do” trip. I thought one would probably learn a lot by going, and it could be fun, but it wasn’t necessary. You could do a great job in Lean without that experience, I said. I didn’t encourage it, and I didn’t discourage it.

Maybe I was rationalizing that I didn’t have a big gap in my Lean understanding because I’ve been learning and practicing this for 20 years without going to Japan. But, I’ve learned from many who came from Japan, visited Japan, and worked there. Maybe that was good enough.

I decided to give it a try – and loved it!

But, I tell you, I became tempted and wanted to go to Japan. I didn’t feel like I NEEDED to go to Japan to study Lean. But, I decided I WANTED to go. I was curious about the country, especially Tokyo. I wanted to see the rural surroundings of Toyota City. I wanted to learn the differences, if I could, between “Lean Culture” and “Japanese Culture” (and our guides helped us understand the difference).

In 2012, I decided to go on a trip led by Kaizen Institute. I loved it so much, I went back in 2014 and a total of five times through December 2019. And I can’t wait to go back again post pandemic.

I knew and trusted them through Masaaki Imai’s work and the great work of others on their team. I went on a week-long all-inclusive trip where everything was amazingly well organized. We had bi-lingual guides who knew Japan and how to help us get around. We toured Toyota, another amazing factory, and two hospitals. We had lectures and discussions that put it all into context. And, we had amazing cultural experiences that I’ll remember for a lifetime.

I’m happy to have the chance to go back with Kaizen Institute in November (if we can find enough attendees). This time, I will have a more formal role of facilitating some of the discussions. I started my career in manufacturing, so I can help the healthcare attendees put things into context. Last time, we had attendees from five or six different countries, so what we learn from those discussions, was great too.

I hope you’ll consider coming. I’m now in the camp of “you should go to Japan — if you want to.” This trip is targeted toward “Lean Healthcare” professionals, but that’s not a hard requirement. Maybe you’ve gone to Japan before, but from a manufacturing perspective, and this would be an interesting way to learn about Lean Healthcare, if you’re considering a career switch or otherwise.

There are many benefits of a trip like this – personally and professionally…

…ideas and inspiration you can bring back to your organization. Memories for a lifetime. As with many things, it’s not cheap… but it’s worth it.

If you’d like to learn more, click here to contact me or click one of the big blue buttons on this page.

I hope you will join us, wherever you are flying from.

Sincerely,

Mark Graban

Author of books including Lean Hospitals and Healthcare Kaizen

Two-time Shingo Publication Award Recipient

Reasons to go to Japan

- You’re inquisitive about Lean and its application as a management system in different industries

- You want to learn the differences and similarities between “Lean Culture” and “Japanese Culture”

- You are up for adventure and a new culture and completely unfamiliar surroundings

- You would like some time to explore Japan and its sites before and after the Lean tour

- You want to take your Lean education and understanding to the next level

Reasons NOT to go to Japan

- Because it’s a trendy thing to do and other hospitals are doing it

- Because you want a vacation

- Because you want to learn more Japanese words to impress and befuddle other people with

- Because Lean is a new concept to you (you’re probably better off reading a bunch of books and getting some experience first)

Talking to Your Boss About the Expense

This is not an inexpensive trip… it’s going to cost about $7,000 in fees for the all-inclusive time in Japan (plus your airfare there and back. Your boss might focus on the cost, but try to think about the value of such a trip.

Some tips and ideas:

- Invite your boss to come along with you (especially if they are a senior leader). You’ll see and learn together and this can help launch the next phase of your Lean journey.

- Use frequent flyer miles for your airfare or pay for the airfare on your own, if you can and your organization will allow it. That shows your financial commitment to the trip.

- Put together a solid action plan (an A3, even) that talks about the goals and expected outcomes of the trip — what are you going to do when you get back? What are you going to teach to others upon your return?

- Timing might be short, but see if you can find a foundation or local healthcare-focused charity to sponsor your trip.

- What other ideas do you have to share that have worked or might work? Contact us and share.

Some of Mark Graban’s blog posts about the trips will give you a sense of what you’ll see and what you’ll learn:

- Highlights From My First Lean Study Trip to Japan, Day 1

- A Japanese Hospital CEO on Kaizen, Innovation & Breakthrough

- Japan Tour Reflections: Taking Home Lean Artifacts or Lean Thinking?

- Japan Trip: Going to Gemba and Seeing 5S at a Japanese Hospital

- A Small Batch of Bread, Other Random Japan Pictures

- Read all posts about the trips

- Podcast with Christian Wolcott, from Kaizen Institute, about the tours